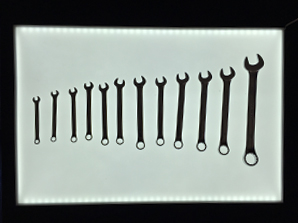

Our Process

We Care for our Work!

Our team strives to achieve excellence in every aspect of the production process, from the preliminary imaging to the aftersales support.

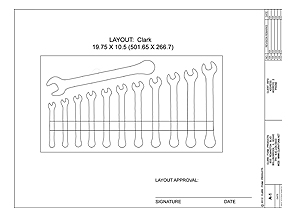

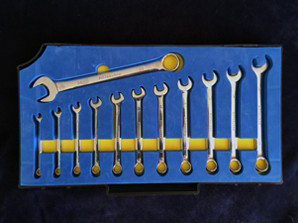

We carefully design our tool liners to be easy and flexible and focus on using the latest 5S tool standards and practices

No matter how difficult or intricate the tool or component might be, you can be confident in achieving an exact drawing. Create hundreds of complete CAD files for a variety of objects in minutes instead of days.